Our new cheese factory is an advanced model of total sustainability.

Sassano has not only taken up the challenge of the UN sustainability goals, but chose to go for the zero-carbon footprint. We invested in the creation of a system which combines existing technologies in an innovative way.

Our factory – the first and only example on the Italian scene – reduced enormously the consumption of methane gas, electricity and water with a collage of advanced technologies. This made us a model of environmental sustainability worthy of imitation.

We self-produce electricity and thermal energy every year, reducing emissions into the atmosphere.

An avant-garde production process was specifically designed for our cheese factory. It valorises the main by-product of the dairy industry – whey – turning it into biogas from which we obtain electricity, thermal energy and agricultural products.

Reliable deliveries, high standards of hygiene and health, and continuous technological innovation towards environmental sustainability have met the highest expectations of distributors, customers, and quality certification authorities.

Sassano has not only taken up the challenge of the UN sustainability goals, but chose to go for the zero-carbon footprint. We invested in the creation of a system which combines existing technologies in an innovative way.

Our factory – the first and only example on the Italian scene – reduced enormously the consumption of methane gas, electricity and water with a collage of advanced technologies. This made us a model of environmental sustainability worthy of imitation.

We have saved 40% on electricity and reduced emissions into the atmosphere.

An avant-garde production process was specifically designed for our cheese factory. It valorises the main by-product of the dairy industry – whey – turning it into biogas from which we obtain electricity, thermal energy and agricultural products.

Reliable deliveries, high standards of hygiene and health, and continuous technological innovation towards environmental sustainability have met the highest expectations of distributors, customers, and quality certification authorities.

Our whey is transformed into water, electricity and thermal energy.

The recovery Cicle

1. The concentrator separates the aqueous part (point 2) of the serum from the concentrate (point 3).

2. Demineralised water is used for washing systems and exteriors.

3. The lactose from the concentrated whey ferments in the anaerobic digester generating biogas (point 4).

4. The biogas powers a cogenerator which produces electrical and thermal energy.

5. The electricity thus obtained is used for the refrigeration systems and for the purifier while the heat from the cogenerator produces hot water.

6. Residual liquids are disposed of via a purifier.

7. The dried residue becomes fertilizer.

our cheese factory

Watch the video

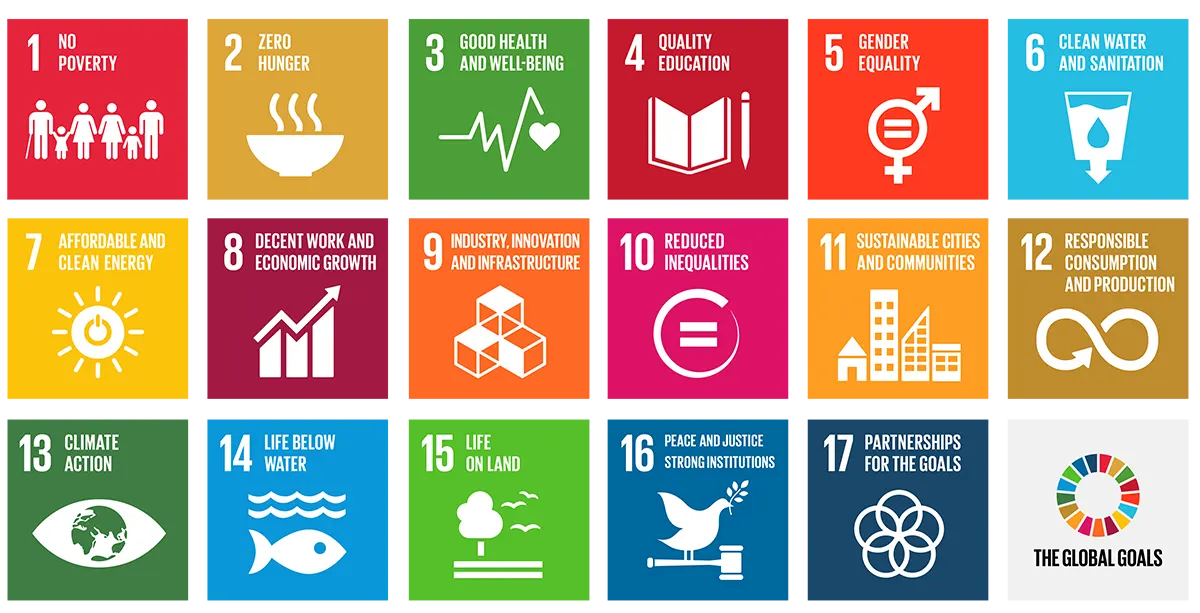

What are global goals?

The Global Goals, also known as the Sustainable Development Goals (SDGs), represent a set of 17 ambitious goals set by the United Nations to address some of the most pressing challenges facing the world by 2030. These goals were adopted in September 2015 by all 193 member states of the United Nations during the United Nations General Assembly.

The main objective of the Global Goals is to improve the quality of life of people around the world by promoting environmental sustainability, economic prosperity, social justice and peace. The SDGs cover a wide range of issues, including poverty, hunger, health, education, gender equality, access to clean water, peace and justice, the health of the planet and many others.

Implementation of the SDGs requires collective commitment at a global level, involving governments, international organizations, the private sector, civil society and citizens. The idea is to create a more equitable, sustainable and inclusive world, where no one is left behind.

By constantly monitoring progress towards these goals and promoting concrete actions at local and global levels, the Global Goals serve as a guide to direct collective efforts towards a more prosperous, just and environmentally sustainable future for all.

Our contribution to the 2030 Agenda

Clean and accessible energy

In 2021, the complex whey valorization plant, the main by-product of the dairy industry, became fully operational. The whey is concentrated internally, used to produce biogas, which in turn is used for the self-production of approximately 50% of the electrical and thermal energy needed by the dairy.

In 2023 we activated a photovoltaic system with 400.4 KW of power which, when fully operational, will allow us to satisfy approximately 20% of our residual electricity needs through renewable sources.

Responsible consumption and production

We have reduced plastic consumption in primary packaging by approximately 36%, through the redesign of the packaging, using smaller and thinner sachets and bags.

We have replaced secondary polystyrene packaging with cardboard packaging.

We have reduced the withdrawal of water from the network, using the water produced by the whey concentration process for the daily washing of the systems.